Make T-shirts like a Professional

Do

you like sewing clothes as much as we do?

Then you would also like to

make your own T-shirts ...

That is possible, it is not

difficult!

Below I explain how it works.

You need a

few things:

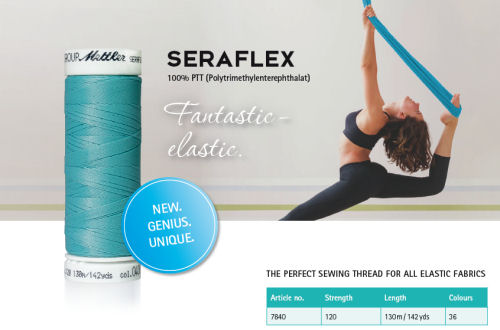

- polyester sewing thread, not

thicker than thickness 100

Tricot or Jersey?

These two names

are used interchangeably to indicate knitted fabrics.

Jersey

is an English word for fine knitted fabric in right-left binding (1

right-1 purl), also called Single Jersey. The name comes from the

English island of Jersey that lies in the channel between the United

Kingdom and France, just off the French coast.

Tricot is a

French word for machine-made fine knit fabric. The garment made from

jersey is also called jersey.

For both Jersey and Tricot, the

raw material (cotton, viscose, rayon, etc.) of the fabric does not

affect the name. Which is the case with, for example, Boiled wool

...

To work!

The trick with working

with stretchable fabrics is not to pull on the fabric when it is

under the machine. Sounds logical, I know! But you pull so easily

that you often do not realize that you do it. Unfortunately I speak

from experience ...

What helps is to place a walking foot

under the machine. Then the fabric is transported above and below at

the same speed. If you don't have one, try to sew Soluvlies tape with

every seam (on the top and bottom of the fabric). That is more work,

but the result just a good!

The yarn

Take

well-twisted polyester yarn. That is smoother and will break and roll

up less quickly. The thickness of the yarn is preferably no thicker

than thickness 100. That is the thickness of normal sewing thread.

For thin knit, I like to use thinner yarns, such as

Alterfil. The

great thing about this yarn is that it has a thickness of 150, is

well-twisted and even has a little bit of stretch!

The

needle and pins

There is still some debate about this. One says

this and the other says that.

The correct needle for sewing

tricot / jersey remains the Jersey needle. In the article

Stretchablefabrics you will find more info about this needle.

The

pins must be sharp and burr-free, in other words: good quality. Also

consider the thinner pins of

Clover

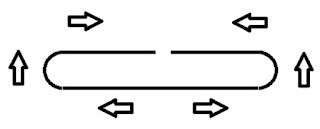

The Stretch stitch

This

stitch is on almost all sewing machines nowadays. He looks like a

lightning bolt. The great thing about this stitch is that it has some

give.

This keeps your seams a

little stretchy, and the yarn does not break when you put on the

shirt.

The twin needle

The twin needle for the hems

of the sleeves and body. See also the article

Versatile Solufleece Tape on this.

Now we can start!

Take

a pattern from a T-shirt. You can draw a pattern yourself or have it

drawn for you. The advantage of this is that the fit is good. If you

don't have that option, take a ready made sewing pattern and check

carefully which size suits you best.

Now we will draw and cut

the pattern.

Then we need the

material.

Before I cut anything out of fabric, I will always

wash the fabric first. Natural fibers tend to shrink a little. It is

a shame if your beautiful new T-shirt has become too short right

after the first wash. What I find most convenient is to pre-wash the

fabric in the same way that I do when it has become a garment. So if

I wash at 40 degrees and I throw it in the dryer, then I also do 40

degrees during the prewash and use the dryer. This way I know for

sure that things will not go wrong later.

We place the

freshly washed fabric on the table with the right side down. Then I

fold both sides of the fabric inwards so that I get two fabric

folds.

Then I will place the

front and back pattern pieces first. I place it against the fabric

fold opposite each other, pin it and cut it out.

The

sleeve is a different story. For this, the fabric must be folded in

half (as it is in the store).

Place the pattern on

the fabric, especially with the sleeve you have to pay attention to

the straight grain. The grain runs from the top down in the middle of

the sleeve. Lay this line parallel to the side of the fabric. And cut

out. If the straight grain is of, your sleeves will turn when you

wear it, I have experienced it myself and believe me it's not

comfortable ...

To cut with a rotary

cutter.

I hear you think a rotary cutter? Yes, a rotary

cutter! The knitted fabrics are often difficult to cut with scissors

due to the stretchiness of the fabric. It's easy to damage the fabric

with the tip of your scissors. Also you lift your fabric a little

when you cut and get uneven seam allowances that way. I find it much

easier to use the rotary cutter. Place a cutting mat on your table. A

cutting mat of 60 x 90 cm is ideal for this, because you don't have

to move your fabric around on the mat. When the pattern pieces are

pinned, you simply cut out with your rotary cutter!

Now

you have laid the foundation. Now the sewing starts, or actually the

basting. If you are not so handy with sewing, I recommend basting.

This way you know exactly how much seam you have cut and where the

points are on the pattern that should come together. This prevents

your garment from hanging crooked or becoming too spacious or

becoming too tight.

Tip: baste just next to the pattern,

so that you can stitch just inside the basted line. Then it is easier

to pull out later.

Finally we can thread

the sewing machine and put the walking foot on.

Sewing

now starts with the shoulder seams of the front and back panels.

Because the material is stretchy, and we do not want the shoulder

seam to stretch while wearing, we stitch a lace tape in the

shoulders

This is how it looks.

Instead of Lace Tape, you can also iron on Bias Tape or Edge Tape in

advance to stitch through later. The point is that the tape you use

does NOT stretch.

After the shoulder seams, the sleeves

are up. Make sure you get the right sleeve on the right side. Sleeves

are not entirely symmetrical. In general, the front of the sleeve (to

the left of the straight grain line) has a slightly lower bend and

the back has a higher curve. Compare it with a spoon: the concave

side is the front sleeve, the convex side is the back sleeve.

After sewing in the sleeves

it looks like this:

Then it is the turn of the

side seams. Sew the side seams of the panels and the seam of the

sleeve in one go. For this I pin the point where the sleeve is

attached to the panels. On the photo you see the "intersection".

Now it is starting to look

more like a T-shirt!

If you are not sure about the

fit, now is the time to put on the shirt.

Tip: Before

fitting, it is wise to stitch through the neck with the stretch

stitch.

(Even if you only wear it for a short while, the

fabric will stretch. Then the neckline can sag. This is almost

impossible to correct and especially difficult when finishing the

neckline.)

The hem

Pin the hem into the fabric,

fold three centimeters. (Slightly over one inch) Check if the hem is

correct. To do this, hold the shirt up at the shoulder seams. You can

also put it on and ask someone to see if the hem is straight. If you

are satisfied, we will fix the

Solufleece Tape on both sides of the

hem and pin. The next step is to baste the tape. Baste 2.5 cm (one

inch) from the side. You can draw a line on the tape with an

Aqua Marker or a

Tailor's Pencil.

|

hem with Solufleece Tape basted on

|

|

| hem with Solufleece Tape and stitching line |

After basting we will sew

with the twin needle. If you want to know more, check out our blog

article

Versatile Solufleece Tape

The stitched hem

with the Solufleece Tape looks like this:

Once washed:

The

sleeve hems are now done in the same way.

Now comes the best

part!

We're going to finish the neckline. For this we cut a

strip of fabric. Can be straight, the fabric already

stretches.

Tip: If you wish to use this finish with a

non-stretchable fabric, the strip MUST be cut diagonally!

The

size of the strip: 4 cm wide. The length is equal to the neck opening

(measure with the pattern) minus 10%. So if my neck opening is 57 cm,

then 10% (5.7 cm) is deducted and the strip will be 51.3 cm long.

|

| go along the ruler with a rotary cutter |

|

| put the ruler on the fabric |

|

| nice straight cut strip |

|

| remove the unnecessary material |

After we have cut the strip,

we are going to make it into a circle. So we lay the strip with the

right side of the fabric facing up. Then we take one end of the strip

and place it at a 90-degree angle with the right side down on the

other end. (good side to good side)

|

| Ends of the strip |

|

| ends of the strip superimposed |

The reason for slanting the

strip is that if you sew it straight and then double fold it, you

have the seam in one place. A thickening occurs in your neck. With

diagonal sewing you shift the seams and there is almost no

thickening.

|

| you see that the seam runs diagonelly |

Then we pin the ends together

with the pin at an angle. The following photo shows how. I always

check if I have set the pin correctly by straightening the strip.

Then I stitch as I pinned,

exactly from the corner of the upper end to the corner of the lower

end.

|

| pressed it looks like this |

|

| now cut the tip off |

Then we pin the strip on

the neck opening.

Divide the strip into four

equal parts, the simplest way is to place the strip on the table and

put a pin on both ends. Then you place the pins together, so you have

two new ends to put a pin in. Voilà, four parts. The same applies to

the neck. Place the shoulder seams on top of each other and place a

pin in the center front and center back. Then lay the pins together

and pin both ends again.

Now you have a strip with

four pins and a neck with four pins. Now pin the strip with the right

side of the fabric on the inside of the neck opening. Place the four

pins of the strip on the four pins of the neck. If all goes well, the

strip is now slightly shorter than the neck.

|

| strip pinned on the inside of the neck opening |

You now stretch the strip a

little to make it fit in de neck. We only reduced 10% so it shouldn't

be too much. If we take out more, the neck will wrinkle. We do prefer

a nice smooth neck ... right?

Then stitch the strip to the

neck.

Now fold in half of the strip and again over the

just stitched seam. Pin in place

|

| fold in half of the strip |

|

| pinned strip |

|

| fold again over the stitch seam |

Then we will stitch it.

and then the T-shirt is ready!

It should look something like

this: